Indoor Air Quality Assessments

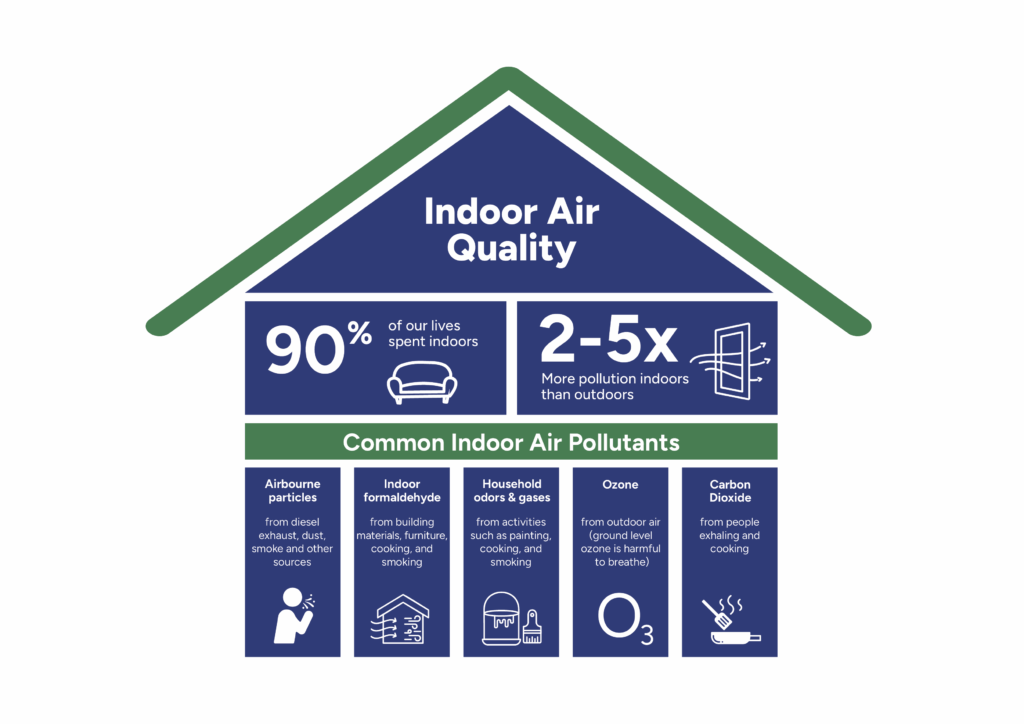

The air we breathe indoors can significantly impact worker health, comfort, and productivity. Poor indoor air quality (IAQ) can lead to discomfort, illness, absenteeism, and in some cases, long-term health conditions.

At Aerem, our indoor air quality assessments help identify, measure, and manage airborne hazards in workplaces, ensuring a healthy and compliant environment for your staff and visitors.

- About The Service

Why Indoor Air Quality Matters

Workplace IAQ can be affected by a range of factors, including:

Inadequate ventilation

Poor temperature and humidity control

Airborne contaminants such as dust, mould spores, volatile organic compounds (VOCs), and formaldehyde

Emissions from building materials, furnishings, or processes

Carbon dioxide (CO₂) and carbon monoxide (CO) build-up

Symptoms of poor IAQ can include headaches, fatigue, respiratory irritation, skin problems, and allergic reactions — often referred to collectively as Sick Building Syndrome.

Our IAQ Assessment Services

- Measurement of CO₂, CO, temperature, and humidity

- Particulate matter (PM₂.₅ / PM₁₀) monitoring

- Biological sampling for mould, bacteria, and allergens

- Detection of VOCs, formaldehyde, and other chemical contaminants

- Assessment of ventilation system performance

Benefits of IAQ Assessments

- Identify sources of airborne contaminants

- Verify compliance with regulatory and best-practice standards

- Improve worker comfort and productivity

- Reduce risk of illness and absenteeism

- Support health and safety risk management

Investing in professional IAQ testing offers far more than compliance — it delivers measurable health, safety, and productivity gains for your workplace.

- Protect Worker Health – Identify and control airborne contaminants before they cause illness or long-term damage.

- Ensure Compliance – Meet WorkSafe NZ requirements and align with recognised international IAQ standards.

- Boost Productivity – Healthy air supports concentration, reduces fatigue, and minimises sick days.

- Detect Problems Early – Spot hidden issues such as mould, poor ventilation, or chemical off-gassing before they escalate.

- Reduce Absenteeism – Fewer respiratory illnesses and allergic reactions mean fewer lost workdays.

- Improve Workplace Comfort – Optimise temperature, humidity, and ventilation for a healthier indoor environment.

- Support Risk Management – Document IAQ performance for due diligence, insurance, and health & safety records.

Regulatory Requirements You Must Meet

New Zealand has no single indoor air quality law, but IAQ is covered under workplace health and safety duties.

- HSWA 2015 – PCBUs must provide a work environment without risks to health, including safe air quality.

- General Risk & Workplace Management Regulations 2016 – Manage airborne contaminants, monitor exposure if unsure, and apply the hierarchy of control.

- Workplace Exposure Standards (WES) – WorkSafe NZ sets limits for CO₂, CO, VOCs, formaldehyde, particulates, and other contaminants.

- Building Code (Clause G4) – Requires adequate ventilation for occupied spaces.

- Industry Guidelines – Standards such as ASHRAE 62.1, WHO IAQ guidelines, and AS/NZS ventilation standards are often referenced in IAQ assessments.

In short: PCBUs must identify, monitor, and control airborne hazards to meet legal duties and keep contaminant levels below recognised limits.

- Pricing

Transparent Pricing & Tailored Solutions

All assessments are customised based on your specific needs. We’ll provide a clear quote before beginning any work, ensuring you know exactly what to expect.

- How It Works

Our Process

1.

Initial Consultation

We discuss your project objectives, site conditions, and any known hazards to understand your requirements in detail.

2.

Site Inspection & Assessment

Our qualified team visits your site to gather information, identify potential risks, and confirm the scope of work needed.

3.

Hazard Identification & Risk Assessment

We assess all health, safety, and environmental risks, ensuring controls are planned in line with the

4.

Scope of Works Development

We prepare a detailed scope of works document outlining:

- The work to be undertaken

- Methodologies and control measures

- Applicable legislation and compliance requirements

- Expected timeframes and deliverables

5.

Client Review & Approval

We review the scope with you, making adjustments where needed to align with your budget, timelines, and operational needs.

6.

Implementation Support

Once approved, we provide project oversight, monitoring, and reporting to ensure the works are carried out to specification.

7.

Completion & Handover

We deliver final reports, certifications, and any ongoing recommendations, ensuring you have full documentation for your records and regulatory compliance.

FAQs

What is Indoor Air Quality (IAQ)?

Indoor Air Quality refers to the condition of the air within and around buildings and structures, particularly as it relates to the health, comfort, and well-being of occupants. Poor IAQ can contribute to health problems such as headaches, fatigue, respiratory issues, and allergic reactions.

Why is IAQ important?

Clean indoor air helps prevent illness, improves productivity, and ensures compliance with workplace health and safety regulations. Poor IAQ can increase absenteeism, reduce comfort, and, in severe cases, contribute to chronic health conditions.

What causes poor indoor air quality?

Common causes include:

Mould and moisture damage

Dust, allergens, and particulates

Inadequate ventilation

Volatile Organic Compounds (VOCs) from building materials, furnishings, and cleaning products

Combustion pollutants (e.g., gas appliances)

Biological contaminants such as bacteria and viruses

How do you test indoor air quality?

Our IAQ assessments use industry-approved methods and equipment to measure pollutants, ventilation rates, temperature, humidity, and other environmental parameters. Samples may be analysed by an IANZ-accredited laboratory for accurate results.

What standards or guidelines do you follow?

We align our IAQ assessments with recognised New Zealand and international standards, including WorkSafe NZ guidance, Ministry of Health recommendations, and applicable AS/NZS and ISO standards.

How often should IAQ be tested?

IAQ testing is recommended:

During building commissioning or after significant renovations

When occupants report health or comfort complaints

Following water damage, mould growth, or chemical spills

As part of ongoing health and safety compliance programs (annual or biannual reviews)

What happens if my IAQ test results are poor?

We provide a detailed report outlining the findings, likely causes, and recommended corrective actions. This may include improving ventilation, controlling moisture, cleaning ductwork, or removing sources of contaminants.

Can poor IAQ affect business operations?

Yes — poor IAQ can lead to reduced staff productivity, increased absenteeism, and potential breaches of health and safety obligations. For businesses, maintaining good IAQ is both a compliance and a productivity measure.

How long does an IAQ assessment take?

Most on-site inspections can be completed in a few hours, depending on the size of the property and the scope of testing. Laboratory analysis may take 2–5 working days.

Do you offer remediation services?

Yes — in addition to assessment and reporting, Aerem Environmental can provide practical remediation recommendations and work with trusted contractors to address IAQ issues effectively.

Get in touch with us

Not sure which service to choose? Get on a call to find your best fit.